EBCTitanium Shims

Titanium shims are an essential addition for enhancing the performance of your high-performance braking system.

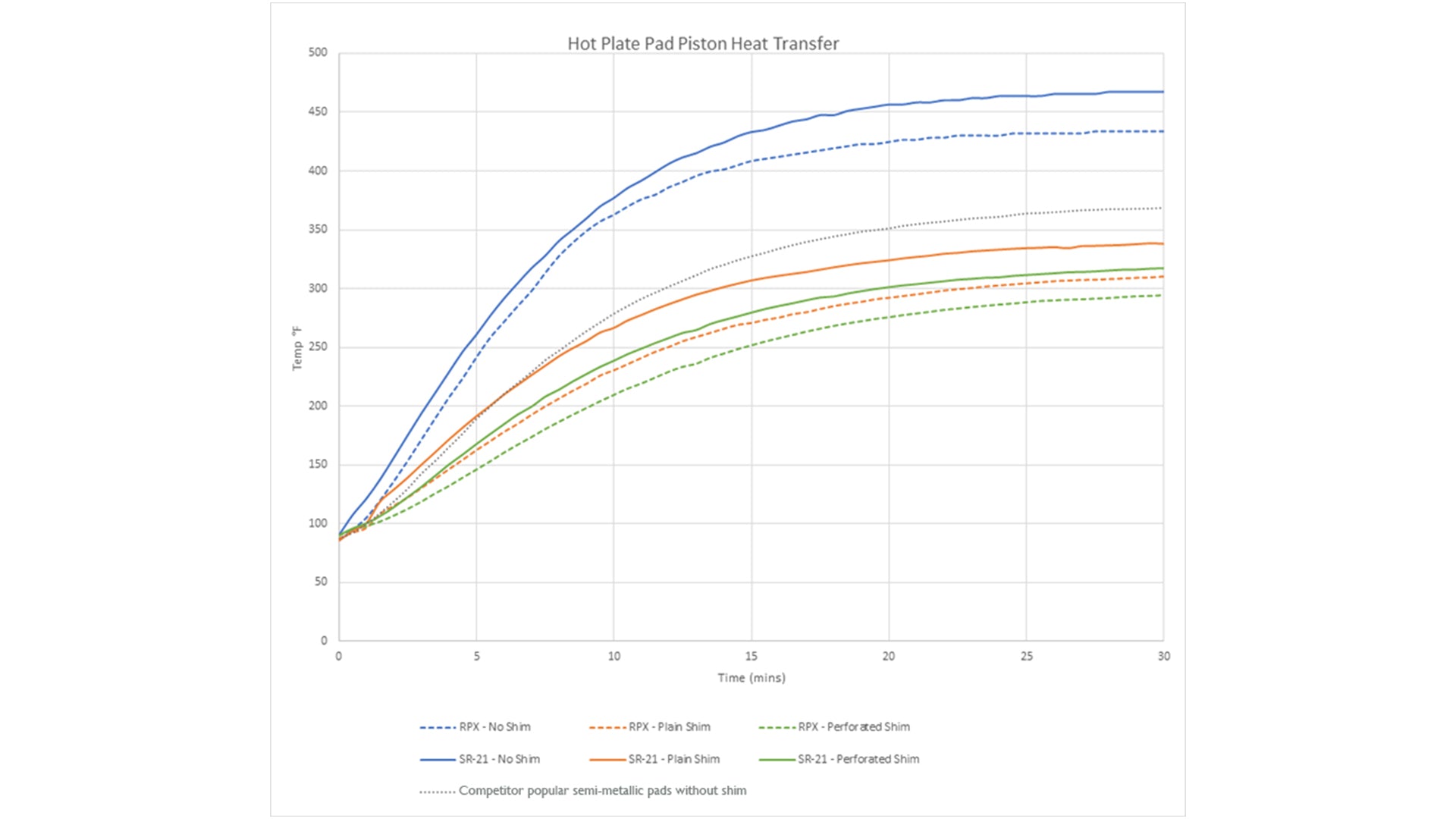

In laboratory tests, these recently introduced perforated titanium heat insulation shims have demonstrated a capacity to reduce heat transfer from the pads to the caliper by approximately 90 degrees Fahrenheit.

EBC Brakes' titanium shims are engineered to diminish heat transmission for a wide range of pad types, as illustrated in the graph provided below.

These experiments were carried out to assess heat transfer in the context of both plain and perforated shims, utilizing EBC race-grade materials. Nonetheless, the fundamental principles involved in these tests remain robust, and the advantages of shim heat insulation should be applicable to any semi-metallic pad.

It is crucial to note that temperatures exceeding 220°C/400°F can potentially harm most caliper seals. Therefore, any measure to mitigate heat exposure to these seals is a welcome development. EBC advises that calipers displaying heat strip readings beyond this threshold should undergo resealing.

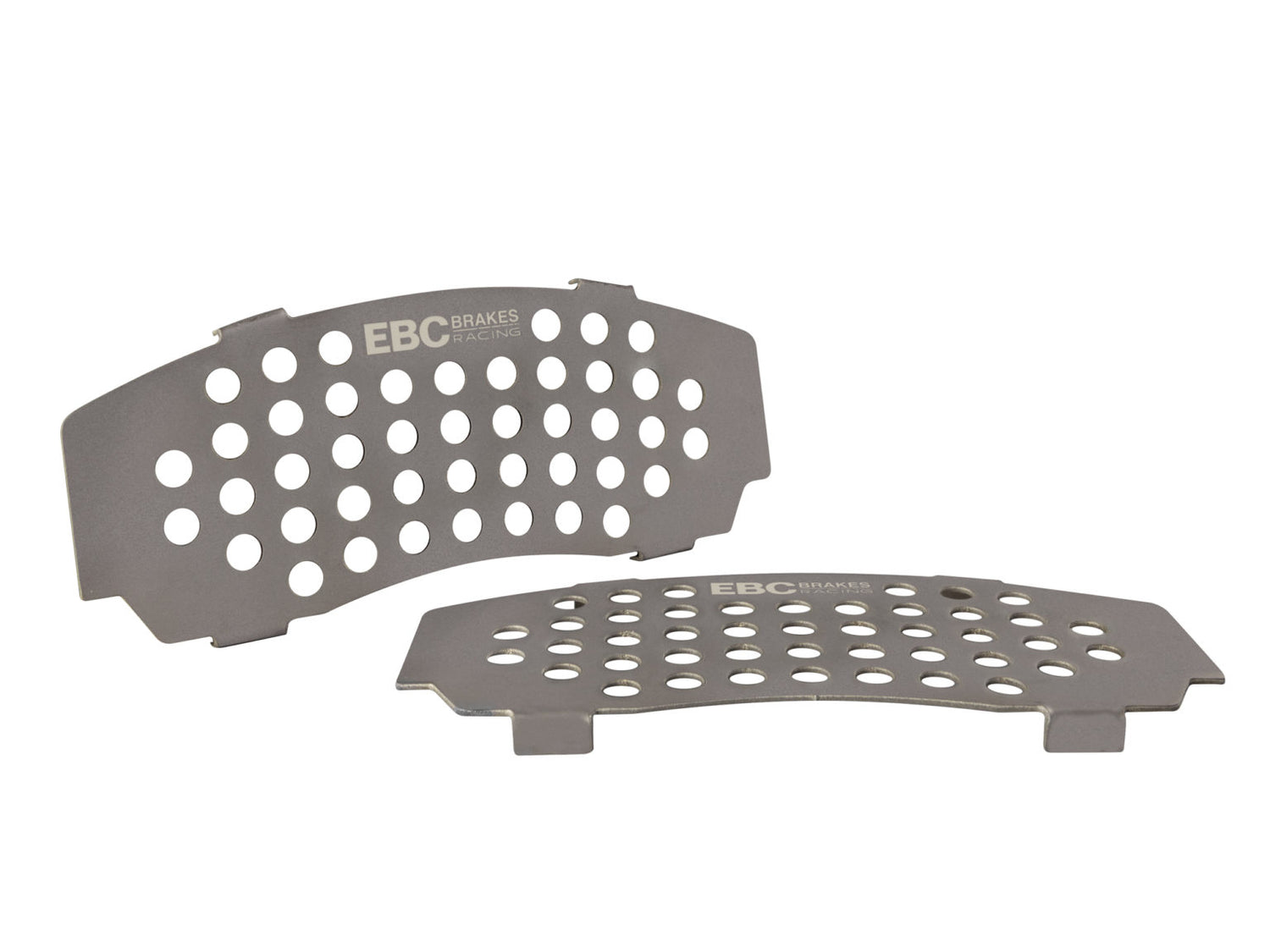

EBC's titanium shims, precision-cut from titanium sheet and designed with perforations to minimize conductive heat transfer, are available in sets of either two or four, contingent upon the caliper type, primarily designed for front installations.

These shims can be readily affixed to your pad set and may be reused during pad replacement unless they exhibit damage.

installation process

Shims should be positioned in a flat manner, ensuring they sit snugly against the rear of the brake pad. In cases where your pad set includes other shims, such as the rubberized shims commonly found on stock pads, it is imperative to remove these prior to installing the titanium shims. This step is essential to prevent an over-thick pad situation.

To remove the existing shims, gently pry them off using a blunt-edged screwdriver or a similar tool to break the adhesive bond. After removal, lightly sand the rear of the pad to eliminate any residual glue or surface irregularities. It is crucial that the new titanium shims are positioned flush against the pad's backing plate, ensuring no debris is trapped in between. This practice is necessary to avoid experiencing a soft or spongy brake pedal.

For sliding calipers, titanium shim sets consist of only two shims, with each one being applied to the pad adjacent to the piston. In contrast, multi-piston calipers are supplied with titanium shims for all four pads within the axle set.

What's wong with rubberised shims?

To clarify, race brake pads from EBC and other brands typically do not include shims. EBC recommends their titanium shims for use with any pad brand, as they effectively reduce heat transfer in high-temperature racing conditions. This advice is universal and not specific to EBC pads generating more heat. All brake pads generate heat during use.

Stock caliper pads often come with rubber-coated anti-noise shims. Replacing these with durable titanium shims is recommended to reduce pedal sponginess and shim distortion. Titanium shims are more resilient and less likely to warp. Unlike OEM rubber shims, EBC's titanium shims are perforated, reducing heat transfer.

EBC conducted tests, as shown in the graph above, indicating that while plain titanium shims offer some benefit, perforated shims are significantly more effective at reducing heat transfer to the caliper.